We are specialized in providing end-to-end consulting and design solutions for cement plants across the globe. With a deep understanding of the cement industry, our team of experienced engineers, designers, and project managers is dedicated to helping clients plan, design, and optimize cement production facilities with efficiency, safety, and sustainability at the core.

Whether you’re building a new plant or upgrading an existing one, our team ensures technical excellence, cost-effectiveness, and compliance with national and international standards.

Our mission is to empower cement manufacturers with innovative engineering solutions, reducing energy consumption and environmental impact while enhancing productivity and profitability.

Engineering Services

Feasibility Study & Project Planning

- Market analysis and raw material availability

- Cost-benefit analysis

- Environmental and social impact studies

- Technical feasibility studies

Basic & Detailed Engineering Design

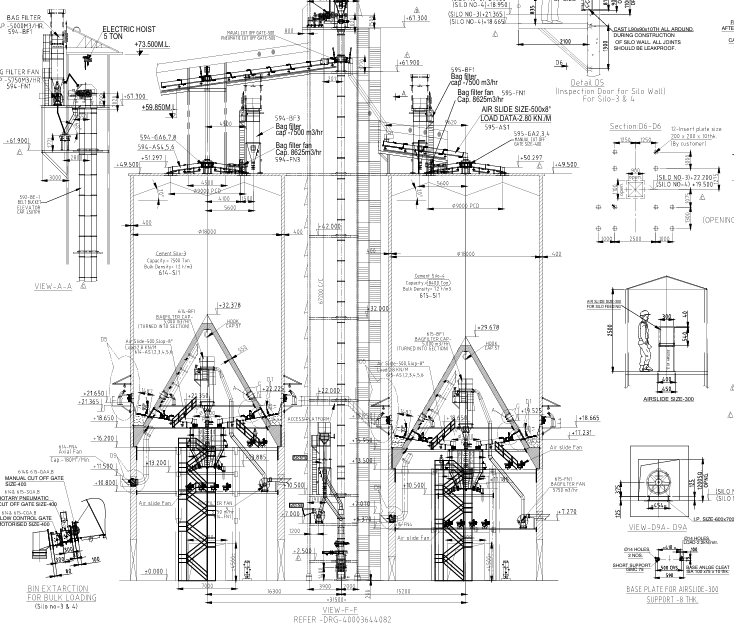

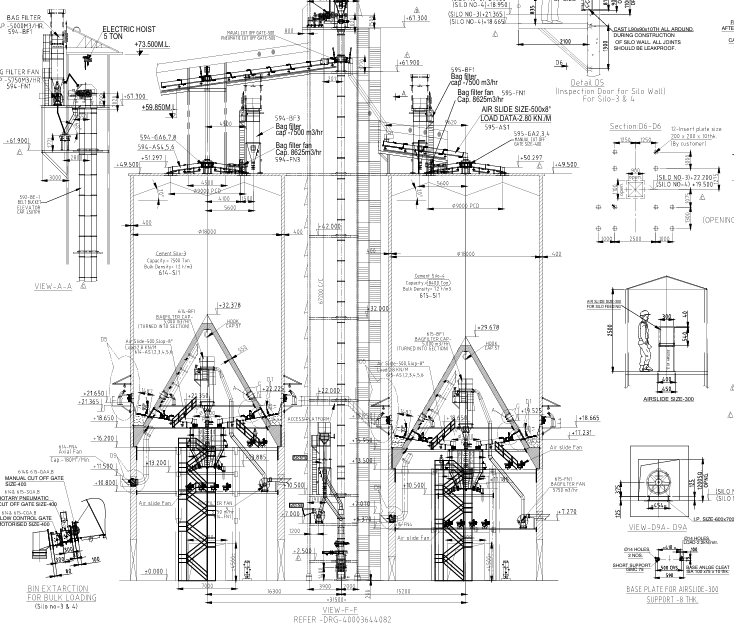

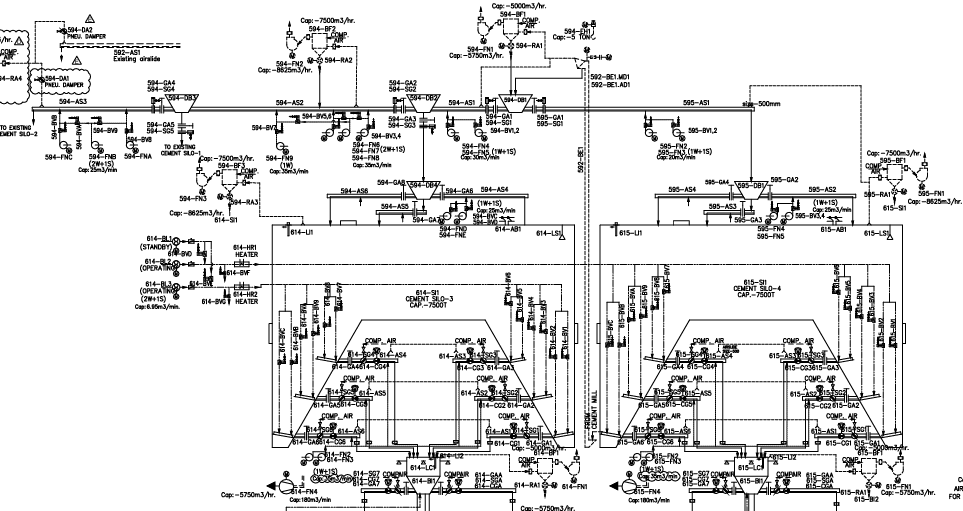

- Process flow diagram (PFD) and piping & instrumentation diagram (P&ID)

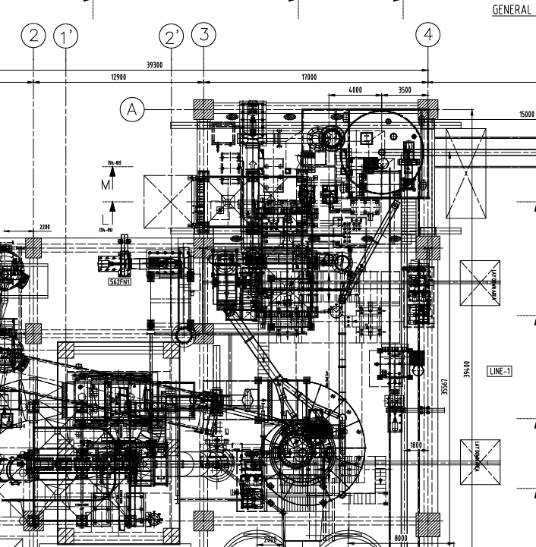

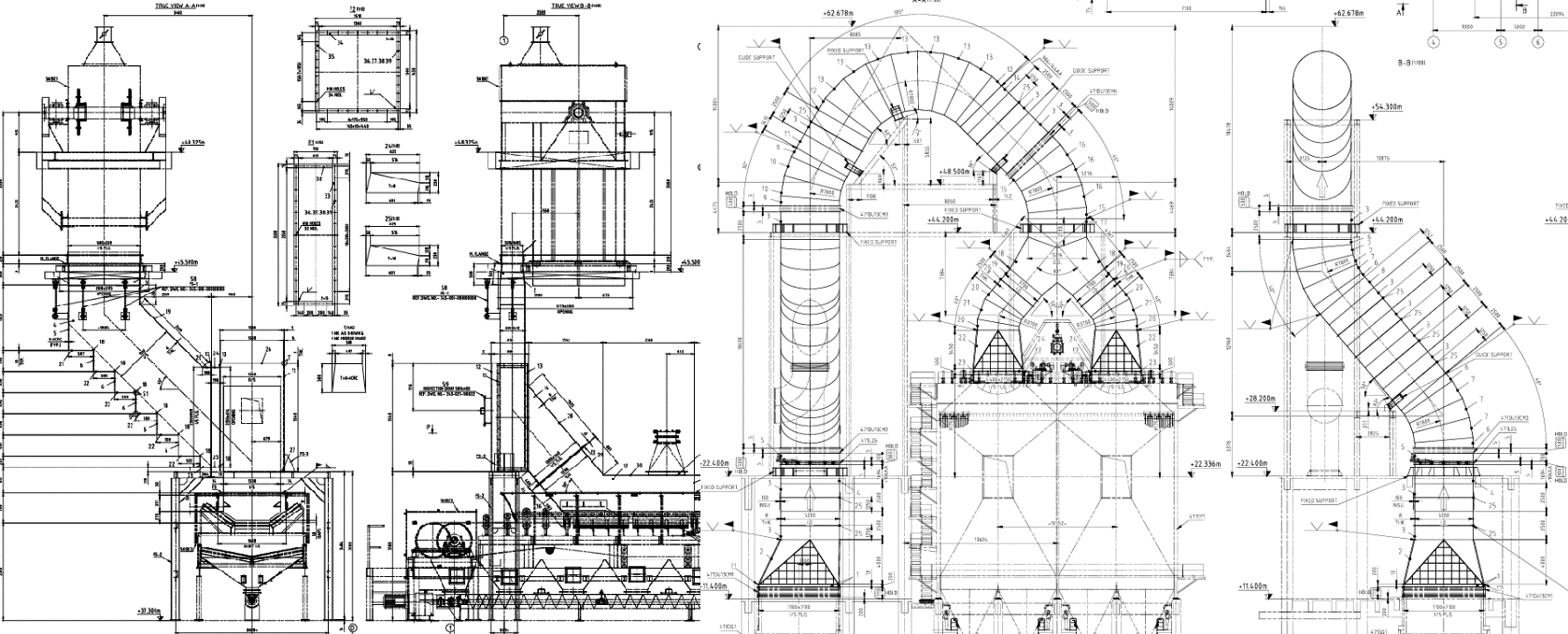

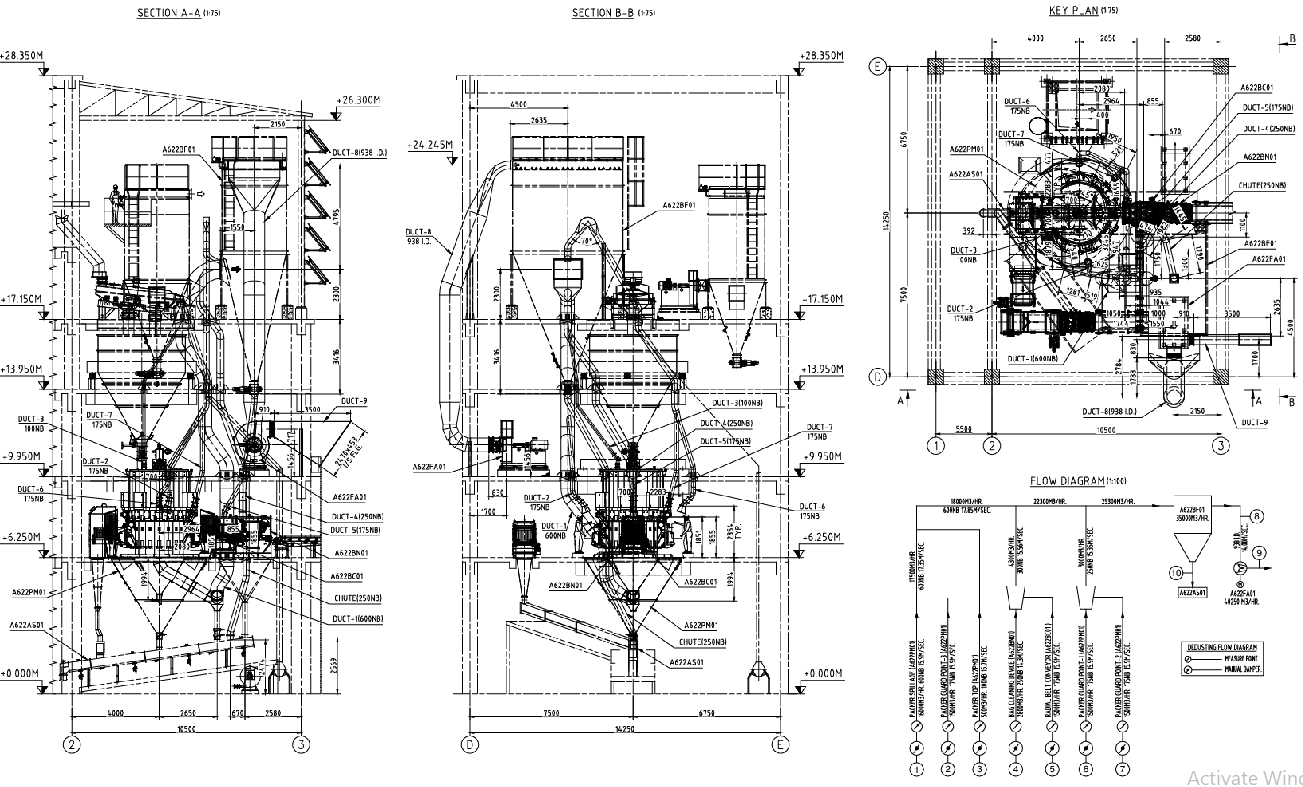

- Plant layout and general arrangement (GA) drawings

- Mechanical, electrical, civil, and structural design

- Instrumentation and control systems design

- HVAC and utility system design

Procurement & Vendor Support

- Specification and selection of equipment (kilns, crushers, mills, etc.)

- Vendor evaluation and technical bid analysis

- Preparation of procurement documents and BOQ

- Inspection and quality assurance of equipment

Project Management & Construction Supervision

- Scheduling and project tracking (using tools like MS Project or Primavera)

- Construction management and supervision

- Safety management (HSE compliance)

- Interface management with civil contractors and OEM suppliers

Energy & Environmental Engineering

- Energy audit and efficiency improvements

- Emission control system design (e.g., bag filters, ESPs)

- Waste heat recovery system (WHRS) design

- Water and waste management systems

Retrofit, Upgrade & Modernization Services

- Capacity enhancement studies

- Replacement or upgrade of outdated equipment

- Process debottlenecking

- Integration of alternative fuels or raw materials (AFR)

Mechanical & Layout Engineering

Comprehensive Plant Layouts

TCEPL delivers accurate and efficient plant layout designs that ensure optimal flow and space utilization.

Key benefits:

- Improved material movement across the plant

- Reduced energy consumption and downtime

General Arrangement (GA) Drawings

GA drawings ensure all components fit seamlessly into the overall design.

Why it matters:

- Eliminates layout clashes

- Efficient equipment arrangement

- Reduces costly reworks during installation

Vendor Drawing Reviews

TCEPL meticulously reviews vendor drawings to ensure smooth integration of equipment.

Benefit:

- Eliminates misalignments

- Facilitates error-free installations

Flow Sheets & Equipment Lists

TCEPL provides detailed flow sheets and equipment lists for clarity and consistency.

- Flow Sheets: Step-by-step process for material flow

- Equipment Lists: Specifies every component required

Design & Detailing of Chutes and Ducts

Properly engineered chutes and ducts reduce spillage and blockages.

What sets TCEPL apart?

- Ensures smooth material flow

- Reduces wear, tear, and operating costs

Venting Design & Detailing

Proper venting maintains air quality and pressure balance in industrial plants.

Added value:

- Enhanced safety

- Reduced emissions

- Improved working conditions

Utilities Sizing, Piping, and BOQ

TCEPL specializes in sizing utilities, flawless piping design, and BOQ preparation.

Why this matters:

- Accurate sizing reduces wastage

- Safe and efficient piping systems

3-D Drawing Preparation

TCEPL uses cutting-edge 3D design technologies for plant visualization before implementation.

Advantages:

- Enhanced visualization for stakeholders

- Fewer on-site errors during construction