COMMON MECHANICAL SPARE PARTS IN A CEMENT PLANT

1. Crusher Spares

Critical wear and replacement parts of crushers for efficient crushing of raw materials.

- Hammers, Blow bars, Jaw plates, Liners

- Rotor assemblies, Bearings, Grizzly bars

- Toggle plates and seats

Working:

Breaks limestone, clay, shale into smaller pieces for processing.

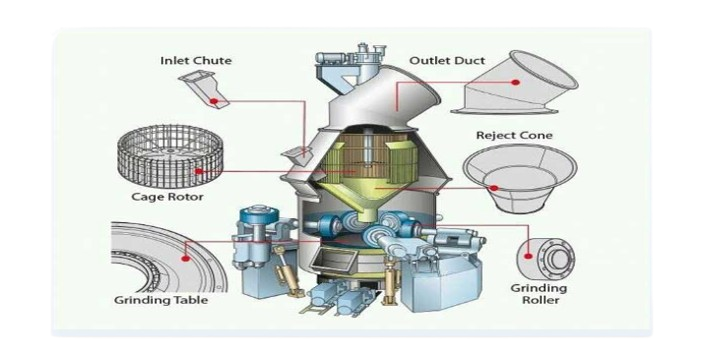

2. Raw Mill / Cement Mill Spares

- Liners, Grinding media, Mill internals

- Girth gears, Pinions, Trunnion bearings

Working:

Raw Mill grinds raw materials into raw meal. Cement Mill produces finished cement.

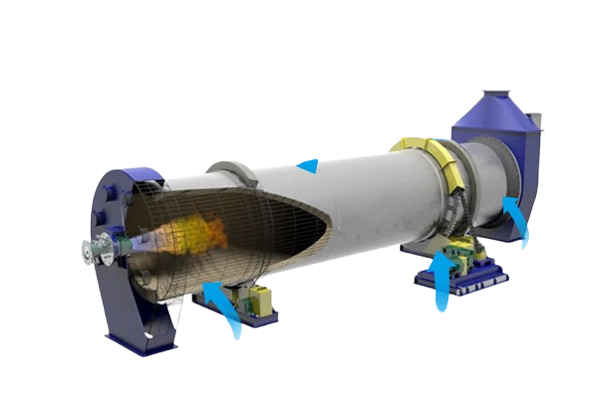

3. Kiln Spares

- Tyres, Rollers, Girth gears, Seals

- Support bearings, Thrust rollers, Chains

Working:

Rotary kiln heats raw meal (~1450°C) to form clinker.

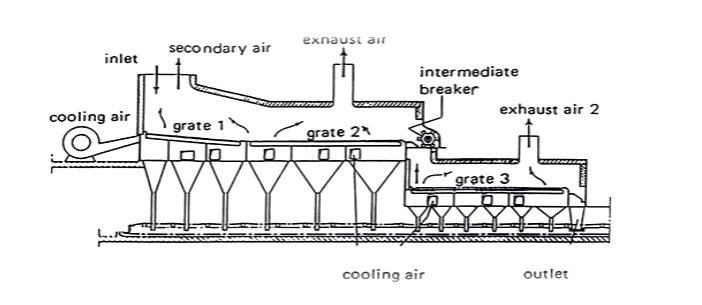

4. Cooler Spares

- Grate plates, Fans, Crusher hammers

- Roller bearings, Hydraulics

Working:

Cools clinker rapidly from 1450°C to ~100°C, improving energy efficiency.

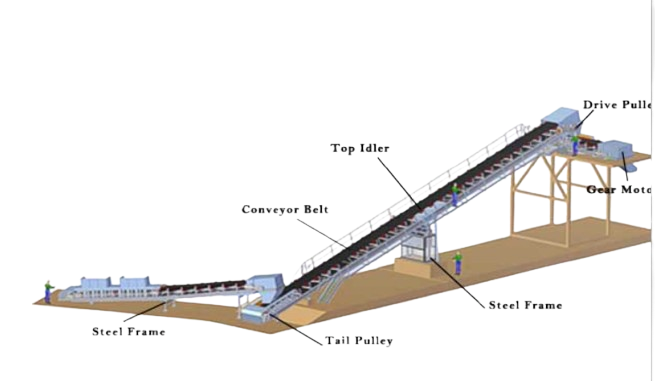

5. Conveyor System Spares

- Belts, Idlers, Pulleys, Scrapers

- Gearboxes, Motors, Chains

Working:

Ensures smooth transport of limestone, clinker, gypsum, and cement.

6. Rotary Equipment Spares

- Seals, Couplings, Bearings, Sleeves

- Shaft assemblies

Working:

Maintain rotating machinery like kilns, mills, fans, compressors, and dryers.

7. Gearbox & Drive Spares

- Gears, Bearings, Shafts, Housings

- Lubrication systems

Working:

Gearboxes reduce speed & increase torque. Drives control speed and torque.

8. Hydraulic & Pneumatic Spares

- Cylinders, Pumps, Valves

- Filters, Hoses

Working:

Hydraulics use oil for high-force tasks, pneumatics use compressed air for fast operations.

9. Miscellaneous

- Fasteners, Gaskets, Expansion joints

- Heat exchangers, Valves & flanges